Easy configuration allows for many different uses that include: limited space applications, Fresh Air firing and reheating of process air streams and SCR inlet heating.

The standard burner comes complete with investment castings (stainless steel), high energy ignition and strong supports for long life. We also supply integral frames and distribution grids. Contact Forney with your project specifications.

Forney duct burners offer reliable performance and dependability to meet the complex needs of the combined cycle and cogeneration industries.

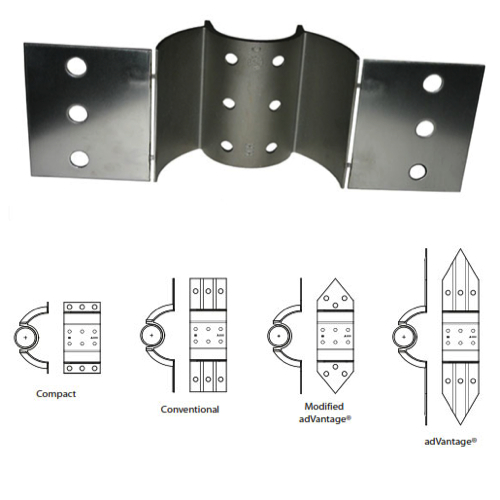

Durable Flame Stabilisers

Investment cast stabilizer design utilizes the cooling effects of the exhaust gas stream to ensure long life and consistent performance.

Reliable Light-off

High Energy Spark Ignition (HESI) is provided as standard equipment for consistent performance in low oxygen and high water vapor environments.

Flow Baffles

Forney includes baffles when needed for improved mixing of gases and shortened flame lengths.

Augmenting Air

Augmenting air is added in unique cases where firing conditions require supplemental oxygen and/or low exhaust gas temperature adversely affect combustion performance.

Integral Support

Supports are included when needed for the duct burner elements to reduce vibration caused by vortex shedding.

Low NOx and Low CO

Forney emissions meet or exceed those required in today’s strict regulatory environment.

Detailed Engineering

A dedicated engineering team ensures the proper design for each project.

Typical Scope:

- Horizontal Burner Elements, Integral Flow Baffles and Supports

- ANSI B31.1 Fuel Skid

- Burner Management System

- Scanner Cooling Air Blowers

- MAXFire® Igniter with HESI

- Flame Scanner

Optional Scope:

- Distribution Grid and Burner Frame (for ease of installation)

- Inlet Fuel Pressure Reduction

- CFD

- Fuel Flow Measurement

- Augmenting Air System

- Interconnecting Piping

- ANSI B31.3 Fuel Skid

Operating Conditions:

Forney duct burners offer customized solutions with flexible operating conditions.

- Heat Input: 10 – 1,100 MMBtu/hr, LHV

- Inlet Exhaust Gas Flow: 30,000 - 5,750,000 lbs/hr

- Inlet Exhaust Gas Temperature: up to 1,250°F

Forney duct burners are used in various applications including:

- Cogeneration and Combined Cycle – Increase steam generation and plant power output.

- Fresh Air Firing – Used as a backup source of hot gas to HRSG/WHRU when combustion turbine is off-line.

- Air Heaters – Heat a large volume of air with minimal pressure drop.

- Process Heating – Many different process streams can be heated, including but not limited to SCR Reheat

applications, Ammonia/Urea Vaporizers and CFB inlet air heaters.