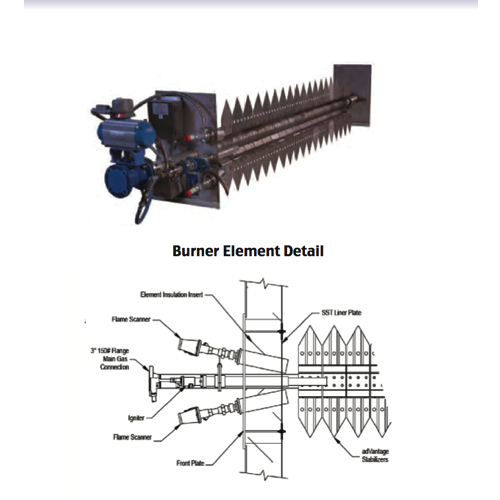

adVantage® duct burners perform in the most challenging conditions.

Premium components and patented technology join to perform like no other duct burner

This design works best in advanced gas turbine applications, especially those with water or steam injection, where low emissions are critical.

Forney’s adVantage® duct burners are optimized for advanced gas turbines that support the critical low emission requirements for water or steam injection applications.

Fuel Types

All gas types

Markets Served

HRSG, Process, thermal oxidisers

- Capacity from 3—322Mw

- Patented Vortex swirl to mix fuel and air

- Works best in low O2 high water applications such as GT exhaust

- Short flame length

- Lox NOx, CO and VOC emissions

- Flame detection with UV scanner

- High energy ignition pilot as standard

- Low CO and VOC Emissions - Up to 80% lower than recirculation type burners – including over turndown

- Low Pressure Drop - Maintained through our patented design with mixing vortices

- Reliable Light-off - High Energy Spark Ignition (HESI) for consistent performance in low oxygen and high water vapor environments

- No augmenting air required - With TEG oxygen greater than 10.5% and water vapor as high as 20%

- Investment Cast stabilizers - Stainless steel stabilizers allow for long life and consistent performance

- Vortex shedding analysis - Performed on each burner to ensure long life and trouble free operation

- Patented design - Provides increased mixing that optimizes the existing oxygen in the turbine exhaust

- Short Flame Lengths - Reduced downstream duct distance and improved temperature distribution from the burner